EXPERIENCE

These are just some of the engineering experiences I am most proud of. Some of them are jobs and others are projects I have done throughout high school and college.

Automated Measurement System using Computer Vision

Spring 2025

Designed, developed, and tested a computer vision system that automates measurement taking using April Tags, GoPros, OpenCV and other open source code.

After seeing how much time my coworkers were spending taking manual measurements of boxes, I knew I could create an application that would automate this manually-intensive process. I created an accurate and modular vision package that was used to build a photo and video application. This system was built using Python, OpenCV, GoPro Hero 13, ArUco Tags, and the oprngopro library. The photo application allows for measurements to be taken over time by snapping a photo when triggered from a robot script. The video application allows for user-friendly active alignment of a tag so test set-up can be easily streamlined.

Vision-Based Autonomous Parking Alignment System for Wirelessly Charging Vehicles

Summer 2024

Programmed Romi to park accurately based on camera identification of the top view of a car.

This project was motivated by how wirelessly charging vehicles will need to have autonomous alignment technology in the future, since wireless charging strictly requires little to no misalignment. My group and myself re-created a garage-like environment where a Romi was our vehicle and we mounted a camera on the roof of our "garage". We trained YOLO8 to identify the top image of a car and calibrated our cameras to return real-time world coordinates of our Romi. Based on the real-time camera-identified coordinates, we programmed and tuned the Romi's differential drive using PID, to accurately park on top of our "charging pad" on the ground. Here is our demos and final report for the project.

Symbiotic Multi-Agent Construction

Senior Year: Fall 2023 - Spring 2024

Designed, built, and programmed an inchworm robot to manipulate smart construction blocks.

Our group successfully built and programmed a modular inchworm robot and a collection of smart blocks. Our build algorithm calculates the steps necessary to construct a user-defined structure. With this algorithm, the inchworm can successfully build with the smart blocks. Individually, I focused on the mechanical design and manipulation of the inchworm. The design of the end-effectors is self-centering using bearings to reduce friction on the selected socket-shape and magnets to help alignment. The manipulation of the inchworm was accomplished by first programming the inverse kinematics in matlab and then altered when testing. Here is a link to our final demo video where we were able to autonomously construct a 3-block column: Final Demo Video

Self-Navigating Robot

Spring 2023

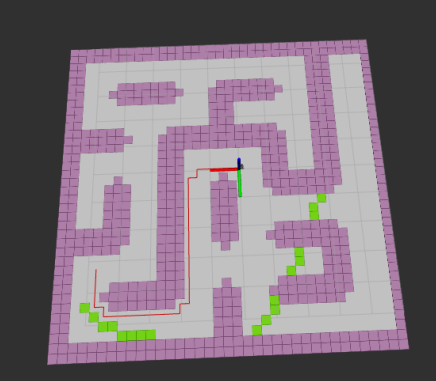

Programmed untethered robot to navigate through field using SLAM.

Programmed untethered robot in Python to map & navigate simulated and physical environments in order to reach a random goal location. We utilized ROS for robot communication, implemented SLAM to synchronous localize and map the unknown environment, and programmed path-planning algorithms (such as A* and Dijkstra) to calculate the best trajectory to the goal location.

Robot Arm Manipulation

Fall 2022

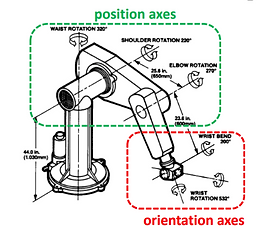

Programmed robot arm to manipulate colored balls.

Programmed robot in MATLAB to find and locate colored balls on field and then command the robot arm to pick up and relocate colored balls. To find the colored balls, we used computer vision, object localization, and intrinsic/extrinsic calibration. To command the arm, we used robot kinematics, trajectory generation, and velocity kinematics.

Prototyping Lab Maintenance

March 2021 - Dec 2024

Fixed and maintained 3D printers, laser cutters, and water jet. Assisted students with projects. Taught machines.

Maintain and fixed thirty Ultimaker and LulzBot TAZ 3D printers, two Full Spectrum Laser Cutters, and one Wazer water jet. Helped students with both creative and class projects. Taught workshops on printers and laser cutters.

Created user manual for laser cutter. Implemented better tacking and labeling system for printer nozzles.

Mapping System

Winter 2021

Programmed robot to scan field and create digital map.

Programmed in C++ to have robot drive along perimeter of random field to create digital map. Manipulated ultrasonic sensor readings to map center of field. Used I2C program on camera to scan field barcodes to program state machine. Tested camera using I2C and UART programs.

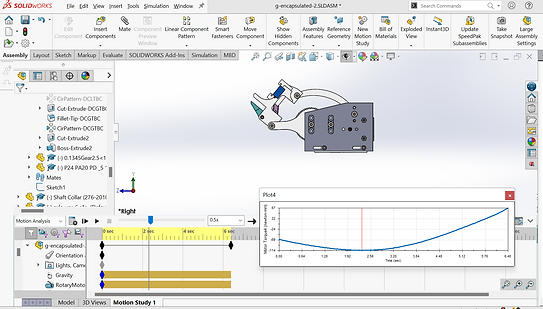

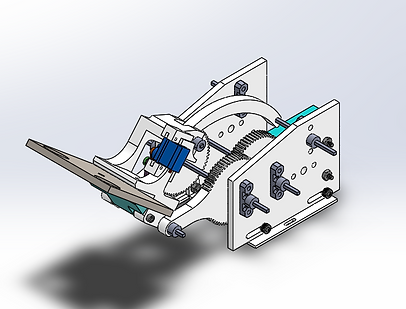

Four-bar Panel Manipulator

Winter 2021

Designed, printed, and programed a four-bar mechanism to manipulate solar panels on surfaces of different heights and angles.

Designed optimal four-bar system using Solidworks and MathCAD to reach three different positions to pick-up and drop-off PLA and metal model solar panels. Developed multiple iterations of four-bar using a laser cutter and 3D printer. Programmed a navigation class in C++ for four-bar to reach different positions.

Morse Display

Fall 2021

Programmed board to display alphabetical letters from morse code.

Using C, programmed Basys 3 FPGA Board to have user input morse code to display alphabetical equivalent. User manipulates switches to intake morse code reading and each of the seven-segment displays alphabetical letters.

Autonomous Bag Pick-Up

Winter 2021

Programmed robot to locate and pick-up randomly placed bags using ultrasonic sensor.

Programmed robot to scan arena for randomly placed bags using a cheap ultrasonic sensor. Manipulated and filtered data to assist with inaccurate ultrasonic readings to make program highly accurate. Scored highest in class.

Programmed photosensor to line-follow. Configured gear ratio for four-bar. Programmed navigation class to navigate field with remote commands.

Turret Scoring System

CAD Lead and Outtake Lead on Team SPYDER

2019 - 2020

Designed and machined outtake system to aim, shoot, and score foam balls into reflective goals of different heights.

Used Creo to design outtake system to aim and shoot horizontally using a turret and vertically using a rack and pinion sliding mechanism. Designed flywheel to control speed, power, and compression of foam balls. Programmed camera to find reflective tape on goals. Machined prototypes and final part with heavy emphasis on our water jet, along with mills, lathes, and laser cutters. Directed small team that assisted with CAD and machining of product.

"Double Axle" Intake System

Machine Shop Lead and Intake Lead on Team SPYDER

2018 - 2019

Designed and machined intake system to pick up and deliver inflatable balls and hatch panels and assist robot in climbing.

Used Creo to design intake system that could actuate two different rotational mechanism independently but on the same axle to manipulate panels and balls. Machined prototypes and final part on mills, lathes, and laser cutters. Directed small team that assisted with CAD and machining of product.